HPA Applications

Semiconductors, Batteries, Optics & More

Ultra-Pure Alumina for the Technologies That Can’t Afford to Fail

From next-gen semiconductors to energy storage, precision optics to photonics, high-purity alumina (HPA) plays a quiet but critical role in the technologies shaping the future.

Alluminous is developing scalable, low energy production of 4N and 5N HPA – engineered to meet exacting requirements across diverse industries.

Where HiPurA® Adds Value

Our HiPurA® platform produces alpha and gamma phase HPA with ultra-low impurity profiles, supporting multiple applications where performance and purity are non-negotiable.

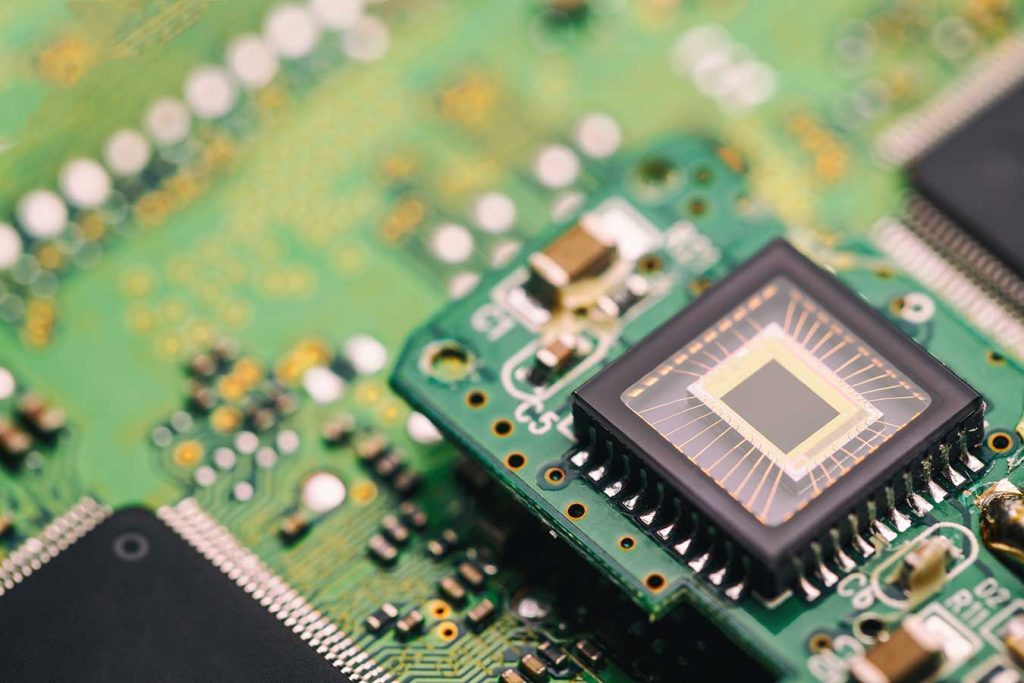

Semiconductor Substrates

- HPA is used to grow synthetic sapphire, which serve as the base for advanced semiconductor wafers.

- Purity is critical – even trace impurities can disrupt the crystal lattice, lowering usable yield.

- Sapphire wafers are increasingly used in wide-bandgap semiconductors for AI, 5G, EVs, defence and aerospace.

HiPurA® Advantage:

High chemical purity supports better crystal yield. Dense pucks or granules can be tailored for optimal sapphire boule production.

Lithium-Ion Batteries

- HPA is applied as a coating on battery separator films to improve thermal stability and prevent short circuits.

- Also under investigation for coatings on anodes and cathodes, and in solid-state battery development.

HiPurA® Advantage:

Our alpha-phase HPA and high-purity boehmite derivatives can support multiple battery chemistries.

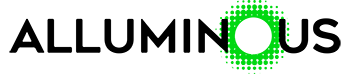

Optics & Photonics

- Synthetic sapphire is used in high-quality optical components, laser’s, IR/UV lenses and sensor windows.

- Synthetic sapphire offers clarity across UV to IR, with strong chemical resistance and thermal stability.

HiPurA® Advantage:

Ultra low impurity HPA produced sapphire of the highest optical properties for many critical markets.

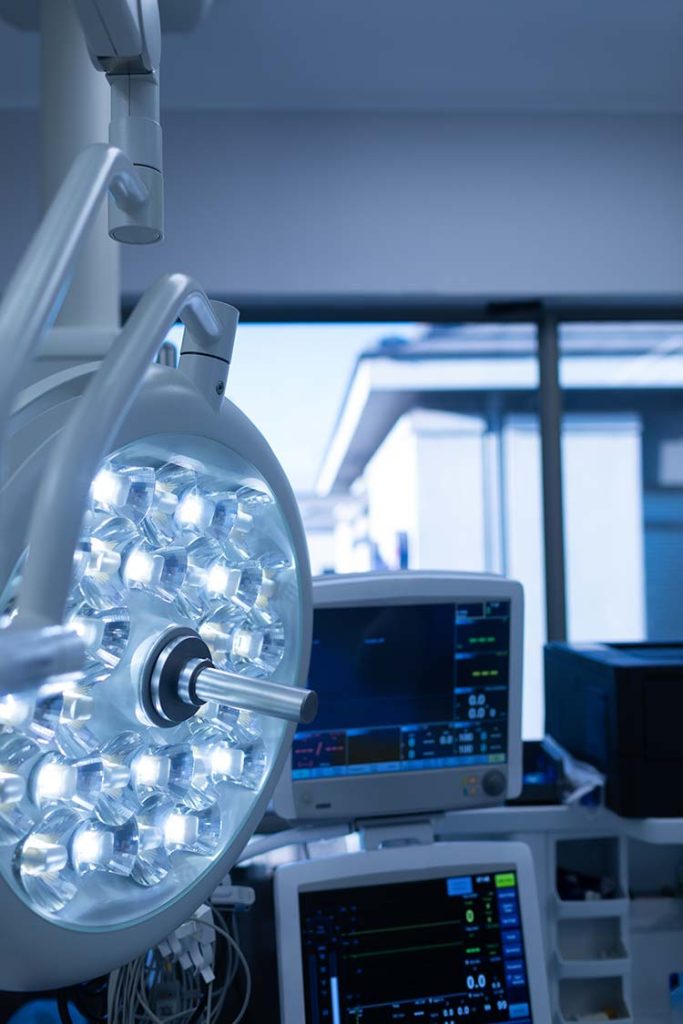

LEDs & Laser Diodes

- LEDs require substrates and encapsulants that can handle heat, light, and pressure without degradation.

- Synthetic sapphire’s stability and excellent optical qualities make it ideal for high-efficiency lighting, displays and photonics.

HiPurA® Advantage:

Ultra low impurity High-purity alumina improves optical performance and component life span.

CMP Slurries & Ceramics

- In advanced chip manufacturing, alumina-based slurries are used in chemical-mechanical polishing (CMP).

- Also used in technical ceramics for wear resistance, bio-compatibility and insulation.

HiPurA® Advantage:

Particle size, surface area, and porosity can be tuned through process control for these specialised uses.

Multi-Product Platform. Multi-Market Reach.

The same HiPurA® platform can support additional high-value materials:

High-Purity Boehmite

Battery separators, ceramic coatings

Aluminium Sulphate

Cathode stabilisers, advanced materials

Aluminium Nitrate

Electrolyte feedstocks, pharmaceutical catalysts

Why Purity Matters

In all of these industrial applications, even minor impurities can reduce yield, efficiency, or safety.

We work with customers to match product characteristics to application needs — whether that’s crystal structure, particle morphology, or trace element profiles.

Industries Served

- Semiconductor manufacturers

- Sapphire and optical component makers

- Battery and EV supply chains

- LED and laser manufacturers

- Technical ceramic and CMP slurry producers

- Distributors and specialty alumina processors